In water electrolysis, electrical energy is used to split water molecules (H2O) into their components: H2 as the main product and O2 as a by-product.

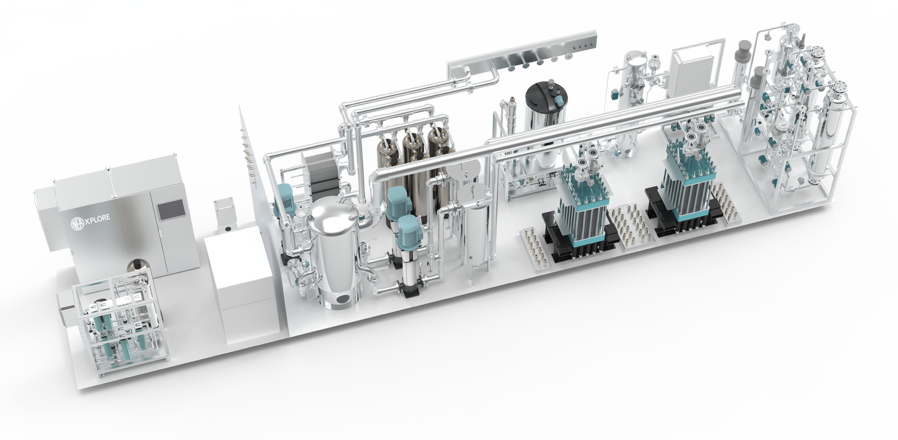

In addition to the stacks in which the electrochemical process is implemented, the electrolysis system contains all the necessary components and subsystems to guarantee an optimized process. Particular attention is paid to process water treatment, heat management and power supply. The gas treatment completes the system and guarantees the ambitious product qualities. The fully automated and self-protecting system is known as the Balance of Plant (BoP) and is divided into the following components:

Two main electrolyzer technologies are currently used in the industry. The first is alkaline electrolysis (ALK), in which a liquid electrolyte (potassium or sodium hydroxide) is used as the starting material. And secondly, polymer electrolyte membrane electrolyzers (PEM), which are fed with ultrapure water. PEM electrolysis offers the advantage of a high-purity process gas and flexible operation. PEM electrolyzers are therefore particularly preferred in connection with volatile, renewable energy systems.

In the context of the EU's decarbonization targets, on-site production of hydrogen by electrolysis from renewable energy sources is an attractive solution. The use of hydrogen as a clean energy carrier enables the storage of large amounts of energy over longer periods of time. It can also play an important role in stabilizing the electricity grid if the share of highly fluctuating energy sources such as wind and photovoltaics in electricity generation increases. If electricity is used exclusively from renewable energy sources during production, the resulting hydrogen is described as "green" and emission-free.

Hydrogen Production per Module (PEM): 10 – 1,000 Nm³/h

Hydrogen Purity: 99.9% – 99.9999% | 3.0 to 6.0

Nominal Discharge Pressure: 10 – 30 bar(g)

Power Consumption: 50 kW – 5.0 MW