Fuel Cells are devices using a fuel like hydrogen, methanol, or methane in connection with oxygen as oxidant. The result of this chemical reaction is direct electricity production. Unlike in a combustion engine or a turbine, there are no moving parts directly involved in that process. Unlike in these machines a fuel does not burn in a flame or explosion, it is an electro-chemical process. In fuels cells using hydrogen, a hydrogen molecule meets an oxygen molecule, and their meeting just results in the production of water, heat and electricity. This meeting is most efficient, when it is warm (around 65°C) and humid and some catalysts like Platinum or Palladium. Most fuel cells are low Temperature PEM Fuel Cells (PEMFC).

In 1838 Christian Friedrich Schönbein detected the fact that hydrogen and oxygen produce a voltage between platinum wires dipped into sulphury acid. More than 100 years later, this effect was used in Fuel Cells to produce electricity in the Gemini and Apollo Missions of the NASA. Another generation later, in 1999 BMW announced a successful test phase of about 5 years with hydrogen driven busses and cars on the Munich airport. Today the fuel cell found its place in passenger cars, busses, commercial vehicles, trains, ferry trucks.

In the mobility sector the fuel cell enables emission free transport without changing the typical habits. The refueling last only 3-5 minutes for a passenger car and the process is identical as the gasoline refueling.

The achievable driving distance is only connected to the size of the hydrogen tanks and the available space to install these. Unlike on Battery Electric Vehicles (BEVs) cold weather does not decrease driving distance drastically. Fuel Cell Electric Vehicles (FCEVs) are very comfortable in use and their only limit is the availability of hydrogen refueling stations.

In the commercial vehicle sector, especially in the transport sector, long range and high load is essential. The energy demand of a truck or bus requires very large and heavy batteries. Here the Fuel Cell has its strength. Fuel Cell powered busses have no limits in range and people capacity. Fuel Cell trucks have no limits in load and can be without limits in range, if enough hydrogen can be carried on the vehicle. Fuel Cell powered busses have no risk of limited range in wintertime and can be easily integrated in refueling strategies.

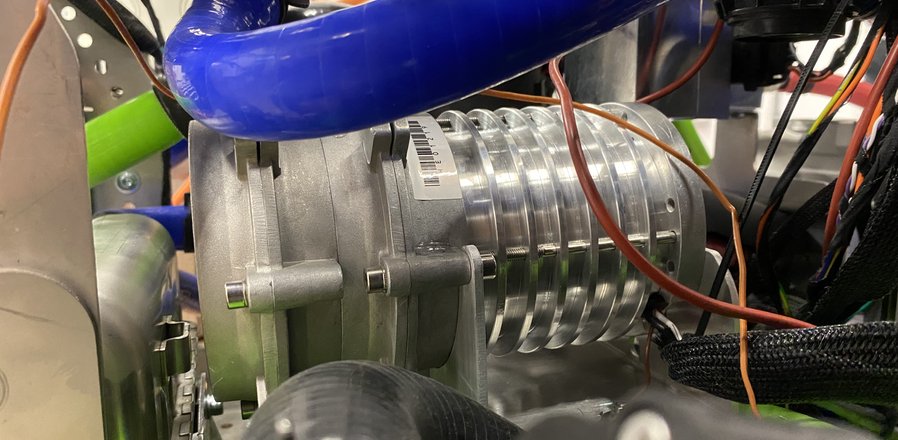

Whilst the industry was looking for large numbers and heavy loads AE Driven Solutions GmbH found that there was nearly now one taking care for emission free transportation in the van and 3,5t class. All these parcel services, courier services and delivery services use these vehicles for the daily service of private people. Due to the increasing use of online shops, the number of parcels and goods to be delivered to households exploded in the last years and will still grow over the next years. In the metropolitan area a purely battery driven van may be sufficient, but in all other scenarios, energy demand and load capability speak for fuel cell driven vans. Apart from range and load, reliably and usability contribute to low costs of the emission free transportation in the logistics sector. Fuel cell driven vans can easy be operated in 3 shifts, since their refueling requires small time only. In addition, AE Driven Solutions fuel cell system is designed for a maximum reliability using the range extender principle in connection with a modified operation philosophy of the fuel cell. Apparently fuel cell systems require not only deep knowledge of the fuel cell stack itself, but a comparable portion of knowledge also lies in the operation and control philosophy of all the components connected to the stack, called balance of plant (BOP). The BOP manages the water and humidity household of the fuel cell stack, the hydrogen supply and the air cleaning and compression. The control of the temperature in connection to pressure and humidity are essential for the performance and reliability of the complete system. An often-underestimated influence has the environment. A journey over the alps or Rocky Mountains produces not only cold air temperature, in connection the humidity of the air at the intake to the fuel cell needs to be controlled and at the same time the air pressure, although the air is very thin in 3000m height. Moreover, a drive through a desert will load the BOP with high air temperature and a lot of dust. All these influences are managed by the BOP and contribute to the efficiency and the reliability of the power supply.

It is self-explaining that a range extender system, having a few operating points only, can be perfectly optimized within its operating envelope. The reduced number of influence factors enable increased performance and perfect tuning of air, hydrogen, humidity, and temperature. This all contribute to the well-being of the fuel cell stack who is the heart of the vehicle.