The mobility sector is today responsible for 19% of global carbon emissions and will be the largest end-user of hydrogen by 2050, with a demand of 285 Mt. [1] The use of lithium-ion batteries is an alternative for achieving zero-emission powertrains for passenger cars as well as light and medium-duty trucks. In use cases that require long distances, long operating times and short charging or refueling times, hydrogen-based powertrains may be both technically and economically more reasonable. Therefore, many truck manufacturers are focusing on fuel cells to electrify the powertrains of heavy-duty trucks. For example, Daimler Truck and the Volvo Group have formed the joint venture cellcentric to develop, produce and commercialize fuel cell systems for long-haul trucks. [3], [4]

This year, NEUMAN & ESSER and Ballard have invested in the Bavarian manufacturer of electric commercial vehicles Quantron. The objective is to accelerate the development of battery electric and fuel cell electric commercial vehicles with a focus on heavy duty trucks. Ballard's investment is intended to support the development of fuel cell vehicle platforms. NEUMAN & ESSER is supporting by providing the necessary infrastructure, in particular electrolyzers and reformer technologies, as well as piston and diaphragm compressors for the transport and storage of hydrogen up to complete hydrogen refueling stations and filling systems. Studies predict that heavy-duty trucks will become the largest end-user of hydrogen by 2050, consuming 110Mt annually.[5]

Battery electric trucks have the highest efficiency (well-to-wheel) with 75 - 85%. In general, the capex is higher compared to diesel or hydrogen combustion engines. In addition, the high weight of the battery limits the payload, which is a relevant factor for trucks. For long-haul freight transport, the charging infrastructure is not yet developed far enough, and the charging time of more than 3 hours is still too high, so that it is not possible to react flexibly to disruptions.

Fuel cell trucks have an efficiency of approximately 35%. The capex is like that of battery electric trucks. [7] Depending on the design, the fuel cell, but especially the hydrogen tanks, can take up differing amounts of space in the vehicle, so that the loading volume is affected. However, with foreseeable innovations in high-pressure tanks, this gap will be closed soon. [8] In contrast to battery electric trucks, refueling times are relatively short with 15 - 30 minutes. To exploit this potential, the hydrogen refueling station (HRS) infrastructure must be significantly expanded.

Truck diesel engines can be powered by internal hydrogen combustion with just a few modifications. Compared with the fuel cell, the hydrogen combustion engine offers a more compact and easier design of the overall system, highly dynamic operating options without any performance losses and the further use of existing production and maintenance resources as well as cost advantages. [9] In an efficiency comparison, the hydrogen combustion engine with 30% is comparable to the fuel cell (35%).

The advantage of synfuels are the existing vehicles and infrastructure. However, their efficiency of just about 20% is the worst of the four powertrains studied. Without regulatory changes, synfuels remain more expensive than fossil fuels and cannot compete with the battery or fuel cell in the long term. Therefore, synfuels are likely to serve as transitional fuels in the coming decades. [10] To integrate electrolysis and compressor technologies into synfuel production with a focus on sustainable aviation fuel, NEUMAN & ESSER acquired a stake in INFINIUM, a supplier of climate-neutral liquid fuels in California, USA in January 2021.

From a Total Cost of Ownership (TCO) perspective, battery electric and fuel cell electric powertrains as well as the hydrogen combustion engine will be the winning technologies for trucks until 2050. [11] In short-haul freight transport, battery electric vans and trucks are already reaching parity with diesel in TCO for certain use cases. The reasons for this are the further declining battery costs and the introduction of specially designed battery electric vans. [12]

But long-haul freight transport has different requirements. Long and unpredictable routes, strict driving time regulations and higher payloads make it difficult to use battery powertrains. At current energy densities, batteries are too heavy and charging speeds too slow to make battery electric trucks economically viable for long hauls. [13] An alternative is provided by hydrogen-based powertrains (fuel cell or hydrogen combustion engine): On the one hand, the faster refueling and longer range can increase the operating time potential of the trucks. On the other hand, the payload capacity can be increased due to the lower weight compared to batteries. Overall, these factors improve the TCO of hydrogen trucks. [14]

By 2035, up to 850,000 fuel cell electric medium-duty and heavy-duty trucks (MDTs and HDTs) could be on the road in Europe. Together, they would consume 6.9 Mt of hydrogen per year, which will require the construction of up to 4,800 hydrogen refueling stations. [15]

Hydrogen infrastructure is often seen as the major challenge in establishing a hydrogen-based logistics system. Hydrogen refueling stations are scarce today. There are currently over 110 hydrogen refueling stations (350 bar and 700 bar) in operation in Germany. [17] In comparison, the number of gasoline and diesel refueling stations in Germany is more than 14,000. Setting up a hydrogen refueling station requires considerable investment as well as a value chain for hydrogen supply.

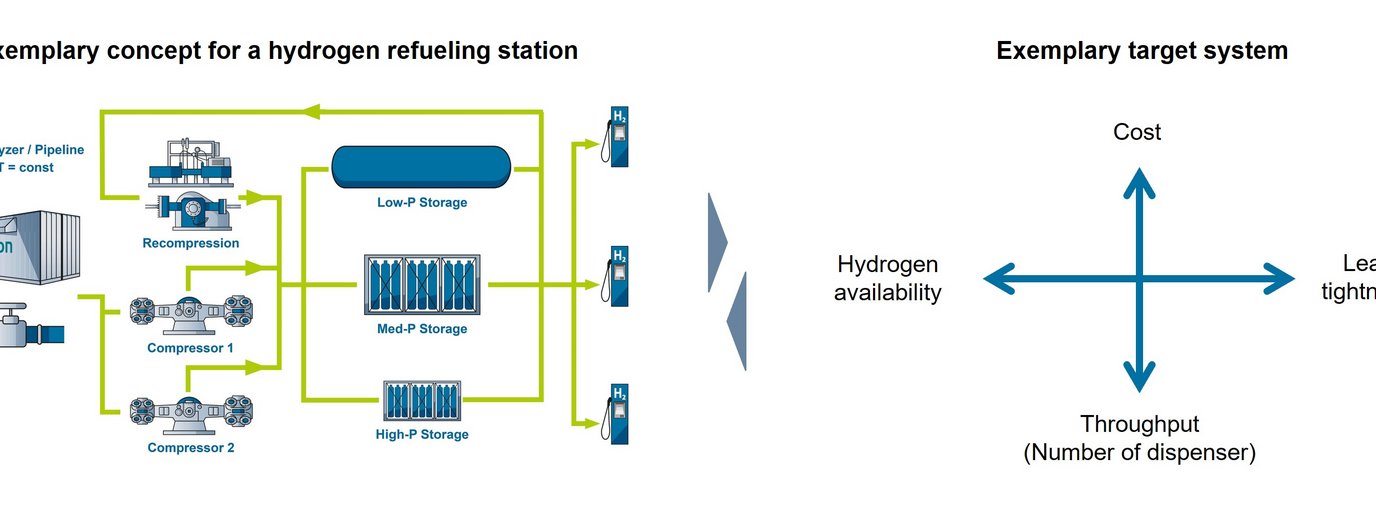

NEUMAN & ESSER plans and constructs hydrogen refueling stations in integrated projects with multiple stakeholders, such as refueling station operators, fleet operators, truck manufacturers and eventually also with stakeholders from politics. In these projects, various concepts for the hydrogen refueling station network are first developed for delimited areas or predefined routes and for the vehicle fleet to be refueled. The concepts are developed using an HRS-simulation program (more information) developed by NEUMAN & ESSER in cooperation with TLK Energy. The concepts include the distribution, the number as well as the design of the hydrogen refueling stations. Among others, the design includes the hydrogen supply, the storage tanks, the cooling system, and the dispensers. The individual concepts are optimized for different target values, which can be represented, for example, by hydrogen availability, leak tightness, throughput, and costs, respectively (see Figure 4). The developed concepts provide the decision basis for the customer to select the most suitable concept according to the requirements of the use case. Once a decision has been made on a concept to be implemented, detailed planning and optimization and the physical construction of the hydrogen refueling stations begin.

NEUMAN & ESSER has signed a cooperation agreement with ShaanGu Europe Research and Development GmbH and Shaanxi Winner Digital Technology Co, Ltd. in 2022, with the aim of developing and building the hydrogen economy in China. The first project has started: A hydrogen refueling station infrastructure for trucks will be established in Shaanxi Province, China. The project is divided into three phases:

In this phase, up to five hydrogen refueling stations will be constructed to supply hydrogen to a small logistics fleet of approximately 10 fuel cell electric trucks. The hydrogen refueling stations on the three planned demonstration routes will be optimally distributed and dimensioned using the above-mentioned NEUMAN & ESSER’s own HRS simulation program.

In the second phase, further 75 hydrogen refueling stations will be constructed by 2025, serving up to 10,000 fuel cell electric trucks. The hydrogen refueling stations will form a harmonized transport system.

In the third phase, renewable energy systems (solar energy, wind energy) are to be established which, in combination with electrolysers, will produce green hydrogen for the transport system. NEUMAN & ESSER has competences in the development and production of alkaline electrolyzers and PEM electrolyzers. The modeling of electrolyzers integrated in hydrogen refueling stations is another feature of the HRS-simulation program.

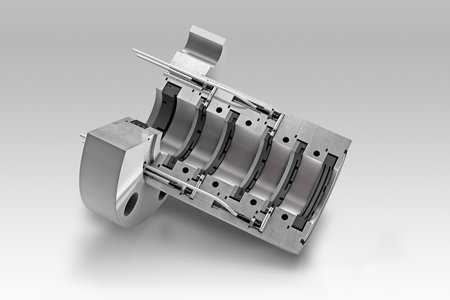

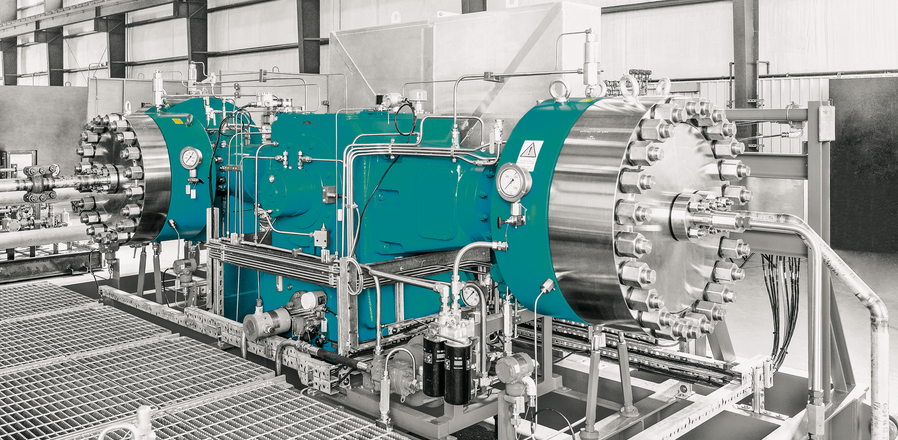

The hydrogen refueling stations are equipped with diaphragm compressors or dry-running, hydraulically driven piston compressors NEA|HOFER TKH, with which the hydrogen can be brought to a pressure of 1,000 bar. Currently, more than 130 NEA|HOFER compressors are installed in hydrogen refueling stations globally. For larger quantities of hydrogen, the integration of a dry-running piston compressor may be necessary. All compressor types mentioned operate oil-free, so that the hydrogen meets the high purity requirements for mobility.

In many applications, it makes sense to integrate an electrolyzer into the hydrogen refueling station, as the hydrogen can then be produced directly on site and refueled in the vehicles. This saves costs that would be incurred if the hydrogen were transported to the refueling station via pipelines or in trailers.

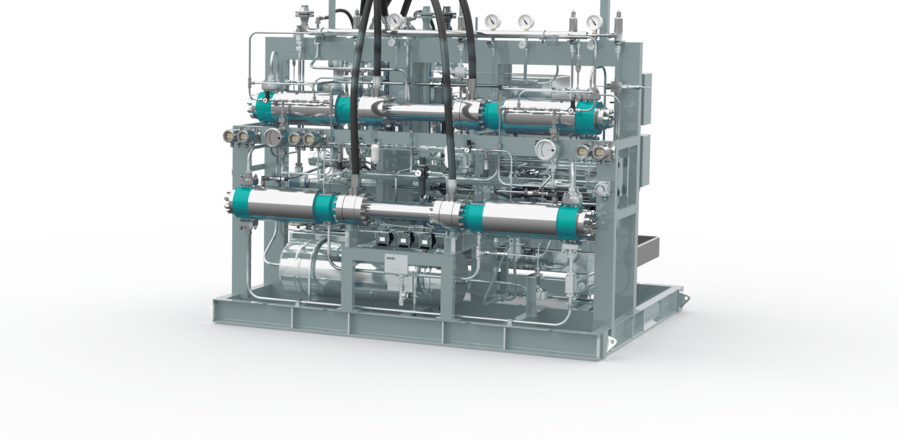

In November 2022, NEUMAN & ESSER sold its first Hydrogen Production and Refueling Station (HPRS). Scope includes a PEM-electrolyser of 300 kW producing hydrogen at 30 bar, NEA|HOFER MKZ diaphragm compressor for 200 and 900 bar, low- and high-pressure storages, a hydrogen dispenser for vehicles refueling, a Generator Set (GenSet) for power re-conversion and complete on-site installation and commissioning services. This turn-key supply will be installed inside UNIFEI University in Brazil for their internal hydrogen mobility demands, in the same state of NEUMAN & ESSER’s office in Belo Horizonte.

[1] Hydrogen Council; McKinsey & Company: Hydrogen for Net-Zero – A critical cost-competitive energy vector, November 2021, P. 16

[2] Hydrogen Council; McKinsey & Company: Hydrogen for Net-Zero – A critical cost-competitive energy vector, November 2021, P. 13

[3] trucknbus.hyundai.com/hydrogen/de [accessed on 12th December 2022]

[4] www.daimlertruck.com/innovation/antriebe/partnerschaften.html [accessed on 12th December 2022]

[5] Hydrogen Council; McKinsey & Company: Hydrogen for Net-Zero – A critical cost-competitive energy vector, November 2021, P. 16

[6] Heid, Bernd; Martens, Christopher; Orthofer, Anna: How hydrogen combustion engines can contribute to zero emissions, June 2021, P. 4

[7] Heid, Bernd; Martens, Christopher; Orthofer, Anna: How hydrogen combustion engines can contribute to zero emissions, June 2021, P. 4

[8] McKinsey Center for Future Mobility: Preparing the world for zero-emission trucks – The mainstays of commercial road transport will soon benefit from cost-effective, zero-emissions horsepower, September 2022, P. 8

[9] www.irt.rwth-aachen.de/cms/IRT/Forschung/Forschungsprojekte-dyn-Liste-/~sklkp/HyInnoICE/ [accessed on 12th December 2022]

[10] McKinsey Center for Future Mobility: Preparing the world for zero-emission trucks – The mainstays of commercial road transport will soon benefit from cost-effective, zero-emissions horsepower, September 2022, P. 8

[11] FEV Consulting: Low carbon pathways until 2050 - Deep dive on heavy-duty transportation, July 2019, P. 5

[12] Heid, Bernd; Martens, Christopher; Wilthaner, Markus: Unlocking hydrogen’s power for long-haul freight transport - As the demand for hydrogen in transportation increases, it is imperative to develop infrastructure to supply trucks, buses, and cars, P. 2

[13] Heid, Bernd; Martens, Christopher; Wilthaner, Markus: Unlocking hydrogen’s power for long-haul freight transport - As the demand for hydrogen in transportation increases, it is imperative to develop infrastructure to supply trucks, buses, and cars, P. 2

[14] Heid, Bernd; Martens, Christopher; Wilthaner, Markus: Unlocking hydrogen’s power for long-haul freight transport - As the demand for hydrogen in transportation increases, it is imperative to develop infrastructure to supply trucks, buses, and cars, P. 2

[15] Heid, Bernd; Martens, Christopher; Wilthaner, Markus: Unlocking hydrogen’s power for long-haul freight transport - As the demand for hydrogen in transportation increases, it is imperative to develop infrastructure to supply trucks, buses, and cars, P. 2

[16] Heid, Bernd; Martens, Christopher; Wilthaner, Markus: Unlocking hydrogen’s power for long-haul freight transport - As the demand for hydrogen in transportation increases, it is imperative to develop infrastructure to supply trucks, buses, and cars, P. 3

[17] App H2.Live [accessed on 12th December 2022]

On June 10, the German Government adopted a National Hydrogen Strategy. “Hydrogen will be a key commodity for a successful energy transition”, said Federal Minister for Economic Affairs and Energy, Peter Altmaier.

In the industrial park Osterweddingen near Magdeburg, the energy transition becomes a living reality. Starting with 2024, the local industrial companies will obtain their hydrogen-gas needs from renewable sources.