NEA|HOFER MKZ diaphragm compressors provide a lubricant and technical abrasion-free compression of gases and gas mixtures. As they operate leakage-free, they are particularly suitable for high-purity applications and for use with explosive, toxic and expensive gases. Our diaphragm compressors are suitable for compressing hydrogen, helium, argon, ethylene, fluorine, hydrogen sulfide, chlorine, monosilane, or nitrogen trifluoride.

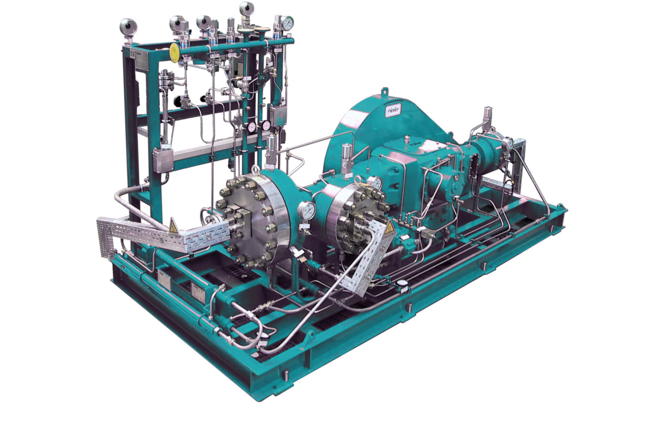

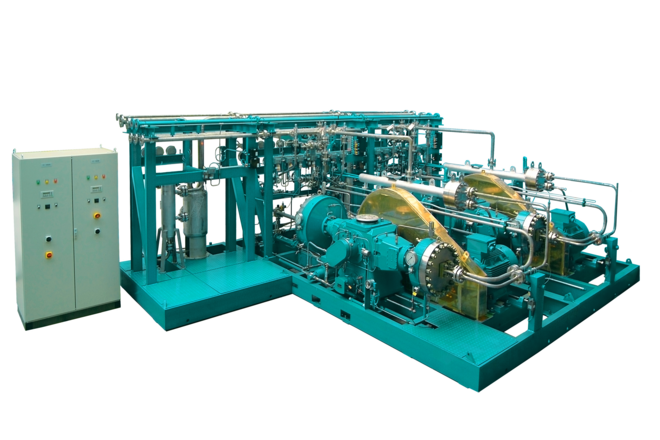

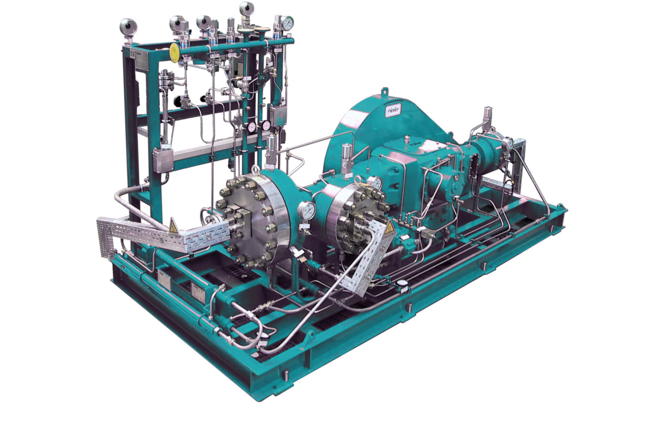

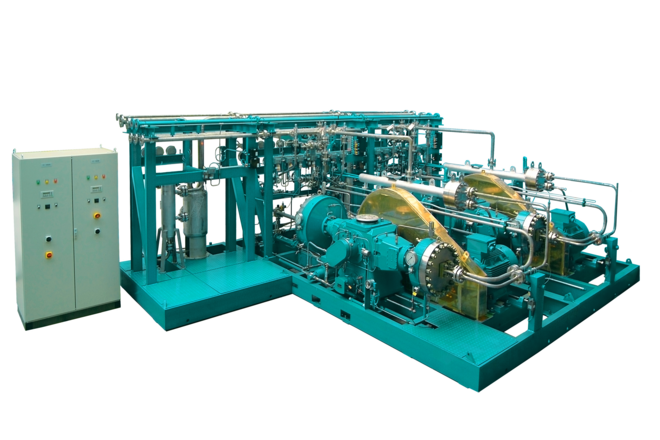

Our diaphragm compressors are typically used, for example, for filling storage tanks, for feeding into continuous processes or as circulating gas compressors. They are characterized by their design specifications, which make the machines particularly safe, reliable, and easy to maintain. We generally provide our diaphragm compressors as complete systems with base frame, drive, pulsation dampers, coolers, fittings (automatic or manual), instruments and controls (optional). However, we also offer diaphragm compressors without auxiliary equipment for installation in your system. Every NEA|HOFER MKZ diaphragm compressor completes a test run under load at our factory, during which the operating data is recorded and documented.

Features at a Glance